Nagase Group attaches importance to quality control and pursue excellent quality in terms of management.

“Quality came from research and development and quality conformity is manufactured”, so we require our employees to put quality awareness into every process of production and operation. In addition, we have established and effectively performed strict quality standards in every detail from materials purchase to product production and from packaging, storage, logistics to delivery.

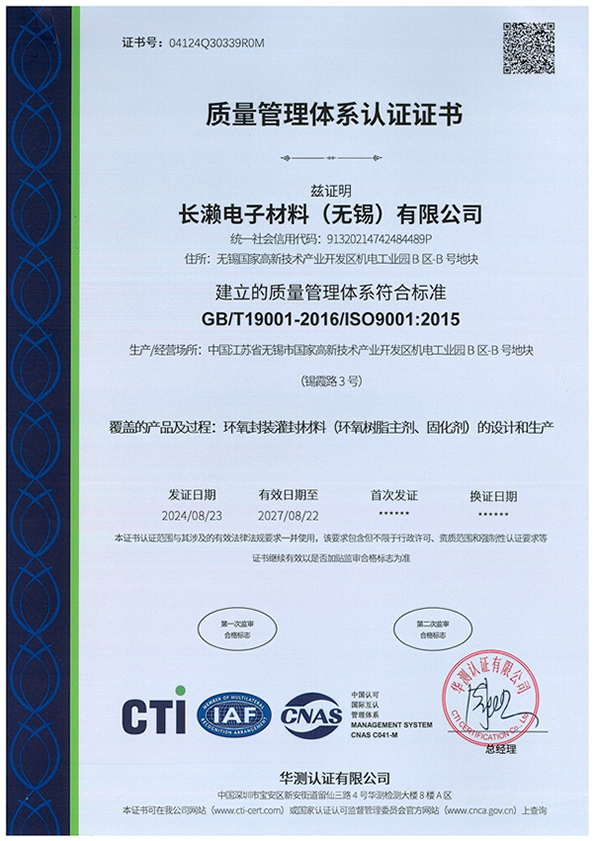

To enable products to comply with automobile industry standards, we started to introduce ISO/TS16949 quality system in 2013 and operated the company based on TS system; in September 2014, the company acquired the certification of TS16949 quality system, thus laying solid foundation for winning automobile industry market in the future.

We have imported equipment and advanced control system which take the lead in the same industry in China, modern production management system, scientific and religious production technique and welltrained employees, so we continue to improve and raise quality and thus achieve high quality of products.

•

Introducing and performing ERP system of QAD Inc.; operating a special QC management system integrating data statistics and trend analysis based on it, so as to monitor the turbulence of quality index

• With 50 years’ experience in recommending, selecting and using materials, Nagase ChemteX (Wuxi) Corporation adopts the materials purchased by Nagase Group worldwide to assure high-quality materials.

• Adopting the three steps of intermediate inspection, product inspection and delivery inspection and holding quality analysis meetings regularly and irregularly.

• Having imported high-precision testing instrument and equipment, such as DSC, TMA, HPLC, electronic universal testing machines, laser particle distribution meter, multifunction automatic titrator and automatic gravitometer model.

• Cooperating with well-known logistics companies to assure timely, safe and accurate delivery of our products. |

|